As the family of alloys, collectively known as stainless steel, continues to grow, their potential applications in the entire industrial field are also expanding. In general, they can withstand the attack of highly corrosive chemicals. These qualities and advantages are particularly important in the chemical and petrochemical industries, and only these fields can produce such high requirements for alloy materials.

In recent years, the emergence of a series of advanced alloys such as so-called "super austenite", "super ferrite" and "dual phase steel" have made stainless steel competing with nickel and titanium alloys under the most demanding conditions . Today, these two industries account for a very large portion of total stainless steel demand.

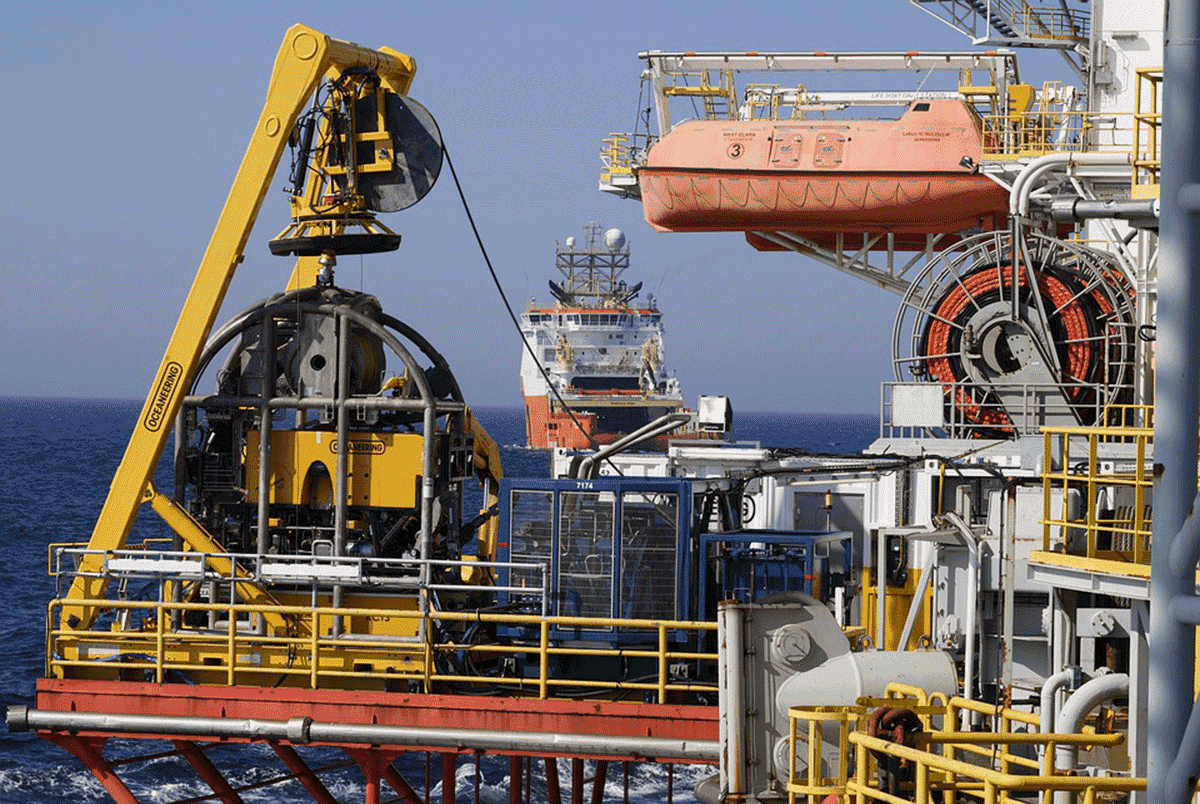

The following materials are commonly used steel materials in the oil field

The use of stainless steel in petrochemical and other process industries can be roughly divided into three areas: corrosion resistance (including cleanliness); heat resistance; high strength.

(1) Corrosion resistance: Corrosion resistance includes cleanliness and beauty, and is the most important requirement for users to adopt stainless steel.

(2) Heat resistance: The application of stainless steel has raised the upper limit of temperature in the petrochemical industry from 600°C in pearlite chromium-molybdenum steel to about 1000°C. The traditional 304H, 316H, 317H, 309, 310 austenitic stainless steel has been widely used abroad. The production of stainless steel for furnaces, such as HK40.HP40. centrifugal casting tubes, has also made considerable progress in China.

(3) High strength: The strength of traditional 300 series stainless steel is not high, especially the yield strength is low. Therefore, stainless steel has long been included in the "low-strength steel" ranks, in order to reduce costs, so increasing the strength grade of stainless steel will bring corresponding economic benefits.

In 2018, dual-phase steel fittings, flanges, carbon steel pipes and other products were used in the Shell oil project in Nigeria, which has reached the export and international standards of steel pipes.