With the development of society and the advancement of technology, steel has become the most basic and important material in production and life. As an important indicator to measure a country's overall national strength, the production capacity of steel is also widely concerned by the society in the production and development of various metal materials.

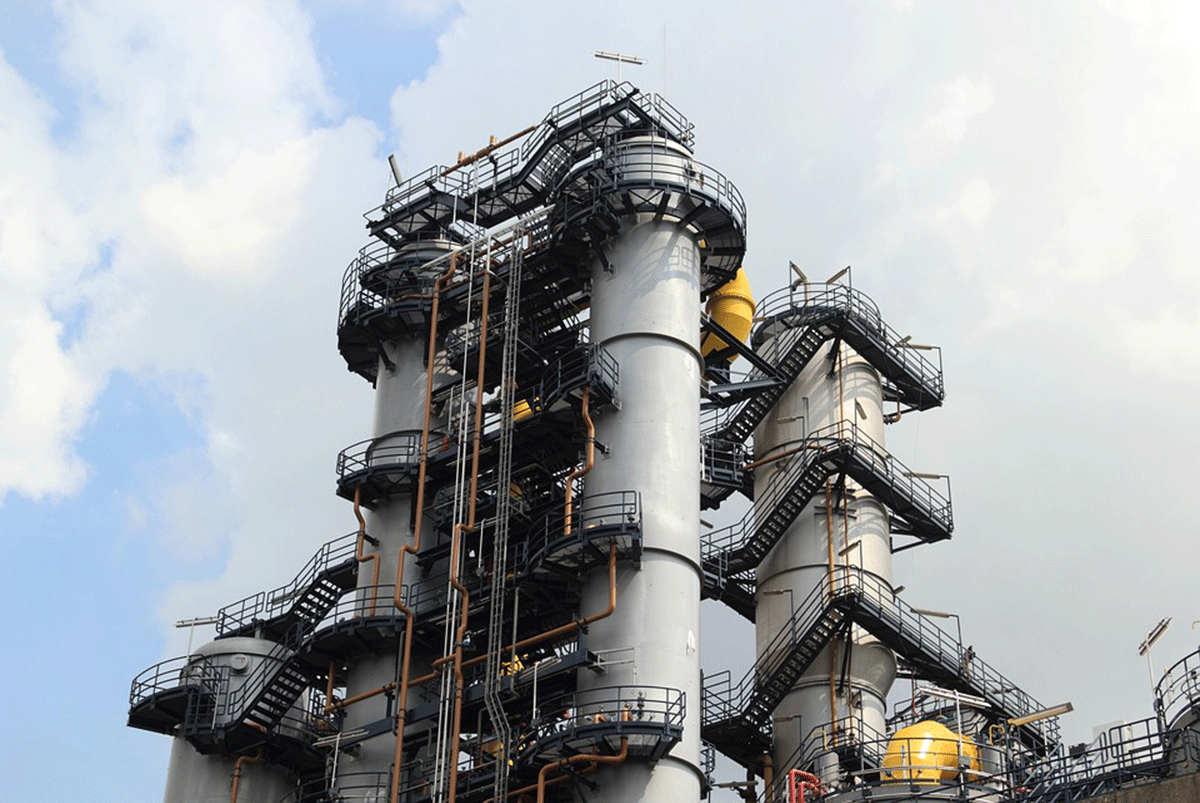

Since the advent of stainless steel, with continuous development, compared with other materials, the good corrosion resistance and comprehensive performance of stainless steel have made stainless steel materials more and more widely used in industry and life, especially in the petrochemical industry. One of the essential materials today.

The following materials are commonly used steel products in the chemical industry

The use of stainless steel in petrochemical and other process industries can be roughly divided into three areas: corrosion resistance (including cleanliness); heat resistance; high strength.

(1) Corrosion resistance: Corrosion resistance includes cleanliness and beauty, and is the most important requirement for users to adopt stainless steel.

(2) Heat resistance: The application of stainless steel has raised the upper limit of temperature in the petrochemical industry from 600°C in pearlite chromium-molybdenum steel to about 1000°C. The traditional 304H, 316H, 317H, 309, 310 austenitic stainless steel has been widely used abroad. The production of stainless steel for furnaces, such as HK40.HP40. centrifugal casting tubes, has also made considerable progress in China.

(3) High strength: The strength of traditional 300 series stainless steel is not high, especially the yield strength is low. Therefore, stainless steel has long been included in the "low-strength steel" ranks, in order to reduce costs, so increasing the strength grade of stainless steel will bring corresponding economic benefits.

In 2010, API 5L X60 line pipe and other materials were used in the refined ethylene project of a company in China. In the case of corrosion resistance (including cleanliness); heat resistance; high strength; low temperature, etc., our products have been widely recognized by customers.